Convection Dryer

Convection dryers utilize convection drying dynamics as their technique to revolutionize the way they remove moisture from materials.In contrast, to drying methods that may not evenly distribute heat convection drying involves circulating air around the material to ensure quick and uniform moisture removal. This method reduces the risk of overheating. Guarantees a drying process for the entire batch.

Reasons to Choose a Convective Dryer

The technology powering convection and convective dryers is well known for its efficiency in operation and precise control. Through the circulation of air convection drying surpasses other methods by effectively reducing moisture in both porous and non porous materials while maintaining product integrity. This effectiveness makes convection dryers and convective drying techniques ideal for tasks that demand moisture control and rapid drying times.

Advantages of Convection Drying

Integrating a convection dryer into your production line offers benefits. This approach enhances both the speed and consistency of drying by optimizing airflow around the material resulting in a process that can accommodate materials and shapes. Additionally convection drying functions, as a process making it well suited for large scale production requirements where consistency and precision’re essential.

Convective dryers not emphasize efficiency but also notably enhance the quality and uniformity of dried products. Convection drying is versatile and suitable, for industries, such, as food, pharmaceuticals, chemicals and minerals. It provides a solution that meets the standards of modern manufacturing practices.

Explore a Range of Processing Technologies

Discover our diverse selection of processing equipment designed to optimize your production line. Explore our comprehensive solutions for your industrial needs:

- Granulators and Extruders: Optimize your granulation process and enhance production efficiency.

- Mixer and Blender: Achieve consistent mixtures for better quality and productivity.

The industrial tray dryer oven is well known for its efficiency and versatility. This drying oven improves efficiency by eliminating air while circulating air inside. It is perfect, for drying materials. Offers various tray choices such, as perforated, wire mesh and flat trays that can be tailored based on size and quantity preferences.

Input: Powders, Granules, Flakes, Strips, Blocks, Pastes, Slurries

Output: Powders, Granules, Flakes, Strips, Blocks with 3%-8% moisture content

Temperature: Inlet air temperature less than 300°C

Additional Feature: Cooling

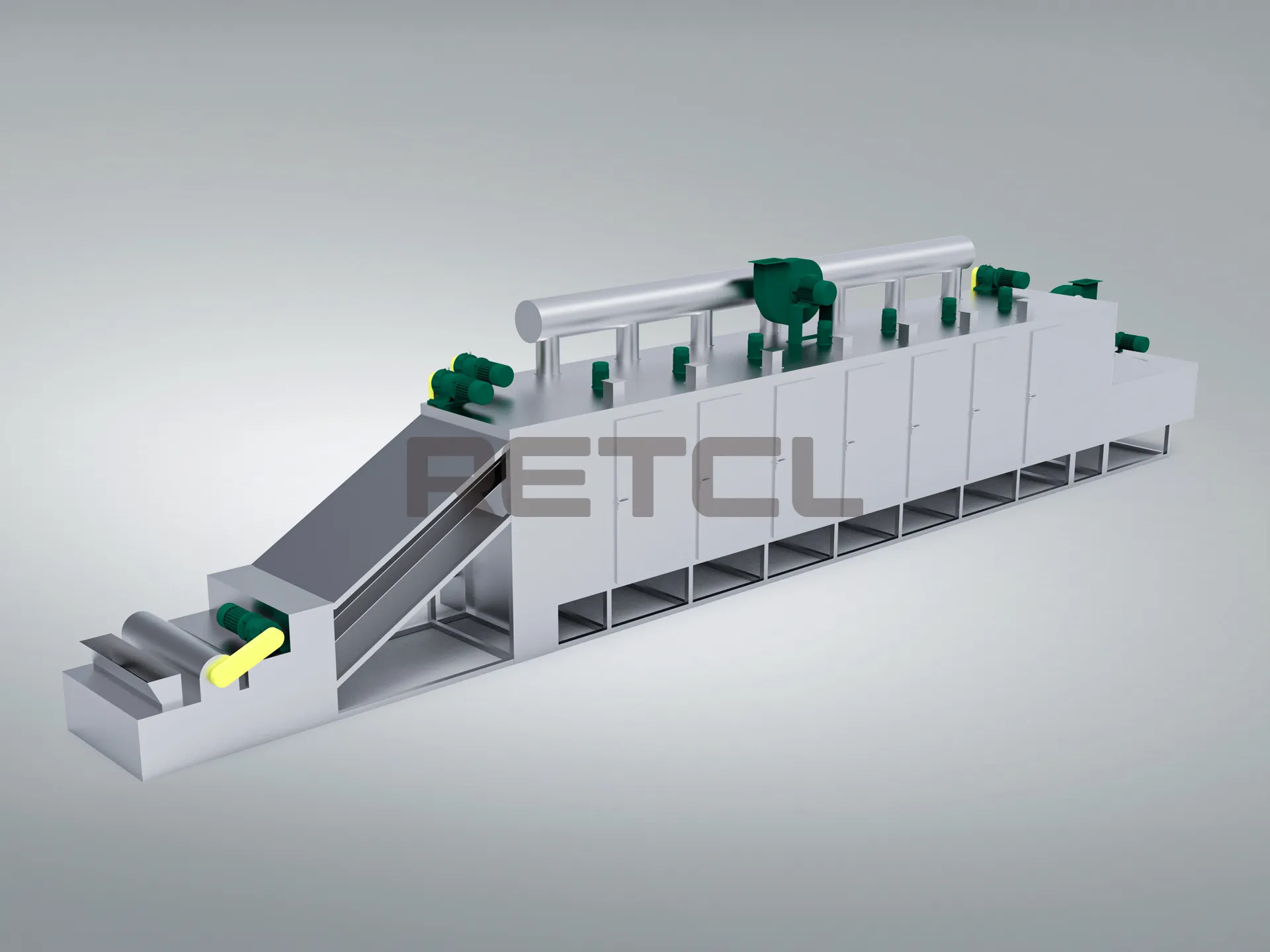

This Belt Dryer can be set up with either one or mesh layers ensuring a spread of materials, for air drying in a particular direction. Its speed can be adjusted depending on the temperature and moisture content of the materials enabling it to operate at temperatures and handle processing of sizable batches.

Input: Permeable solids in sheets, strips, granules or blocks

Output: Sheet, strip, granule or block solids with 3%-8% moisture content

Temperature: Inlet air temperature <200°C

Additional Feature: Cooling

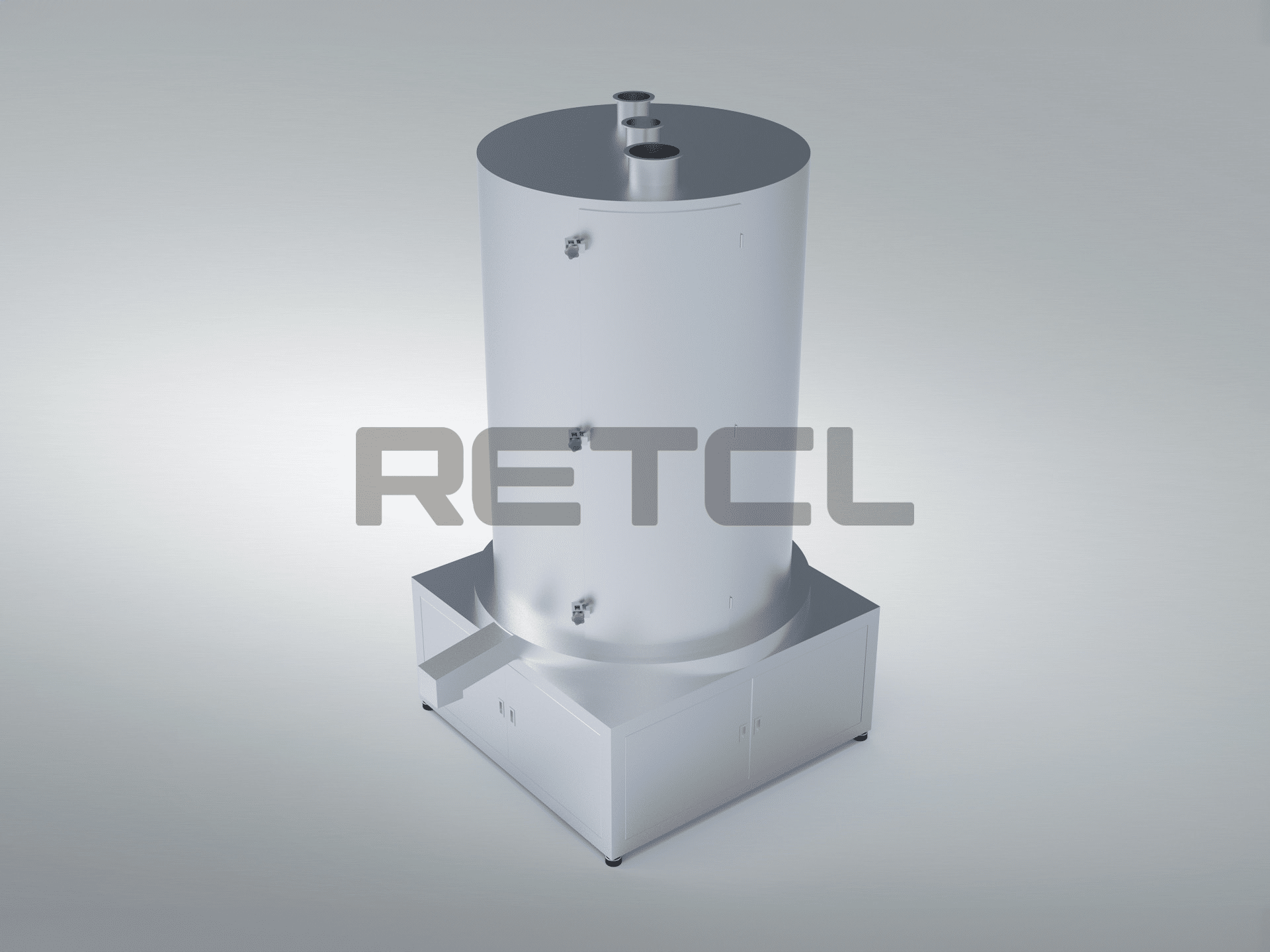

The Vertical Fluid Bed Dryer stirs materials to create a fluidized bed with air promoting contact, for quick drying or cooling. Specifically designed for batch production it allows for bed heights than horizontal fluidized bed dryers commonly paired with wet granulation machines.

Input: Powders and Granules, moisture <20%

Output: Powders and Granules, moisture 3%-5%

Temperature: Inlet air temperature <100°C

Additional Feature: Convertible to a spray fluidized bed granulator

The Vertical Blending Fluidized Bed Dryer comes equipped with a mixing mechanism that aids in creating a fluidized bed within the container when handling heavy loads. This device is ideal for mass production. Is capable of processing thick substances typically paired with wet granulation setups.

Input: Powder and Granules,moisture <20%

Output: Powder and Granules,moisture 3%-5%

Temperature: Inlet air temperature <100°C

Additional Feature: Stirring,Cooling

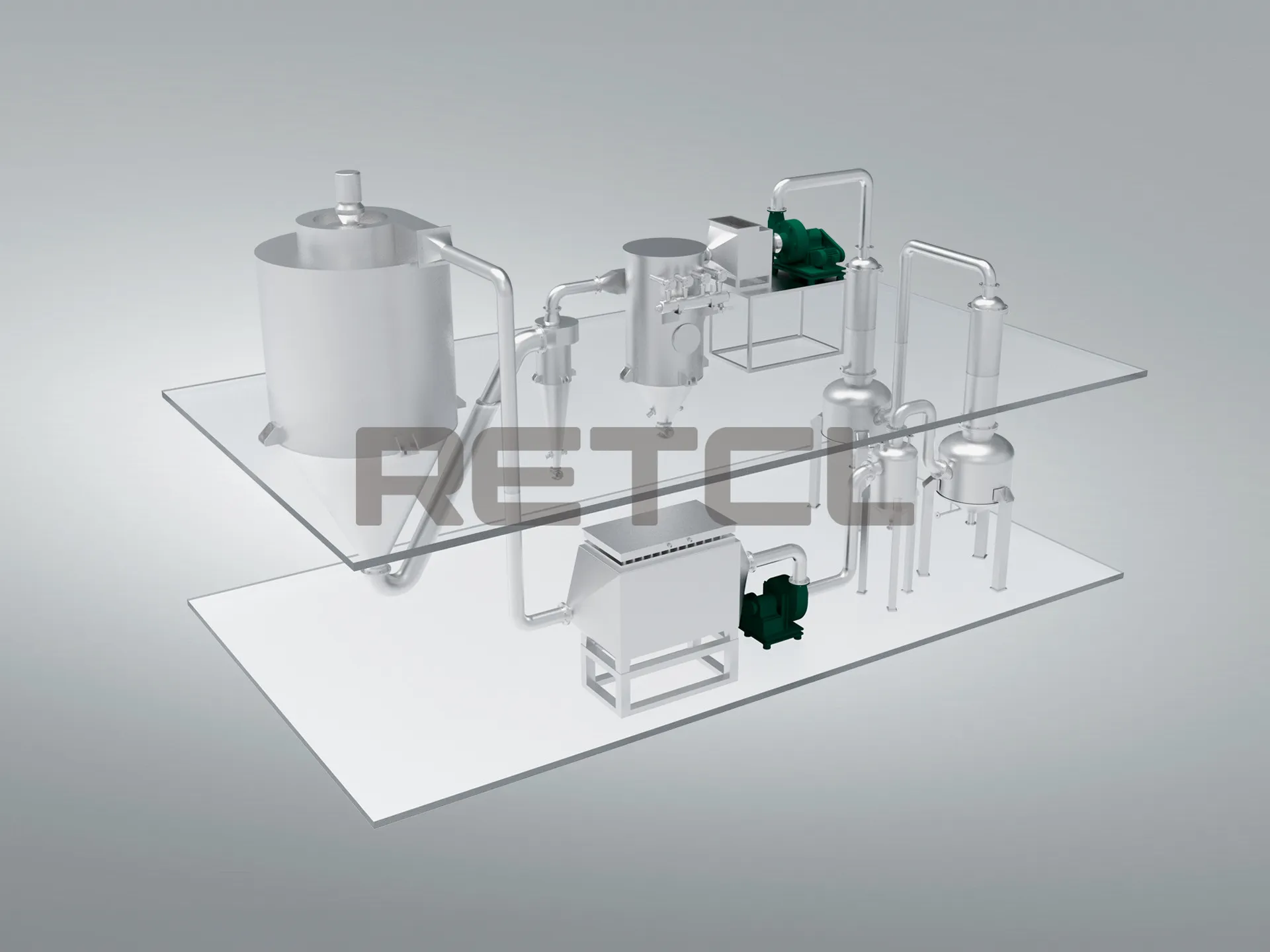

This explosion-proof spray dryer operates in a sealed environment, using inert gas as the drying medium, perfectly recovers solvents from raw materials. The recyclable drying medium ensures superior protection for sensitive materials.

Input: Solutions, Emulsions, Suspensions

Output: Powder with 3%-8% moisture content

Temperature: Inlet air temperature range of 100°C to 300°C

Suitability: Anaerobic, explosion-proof and low-temperature conditions

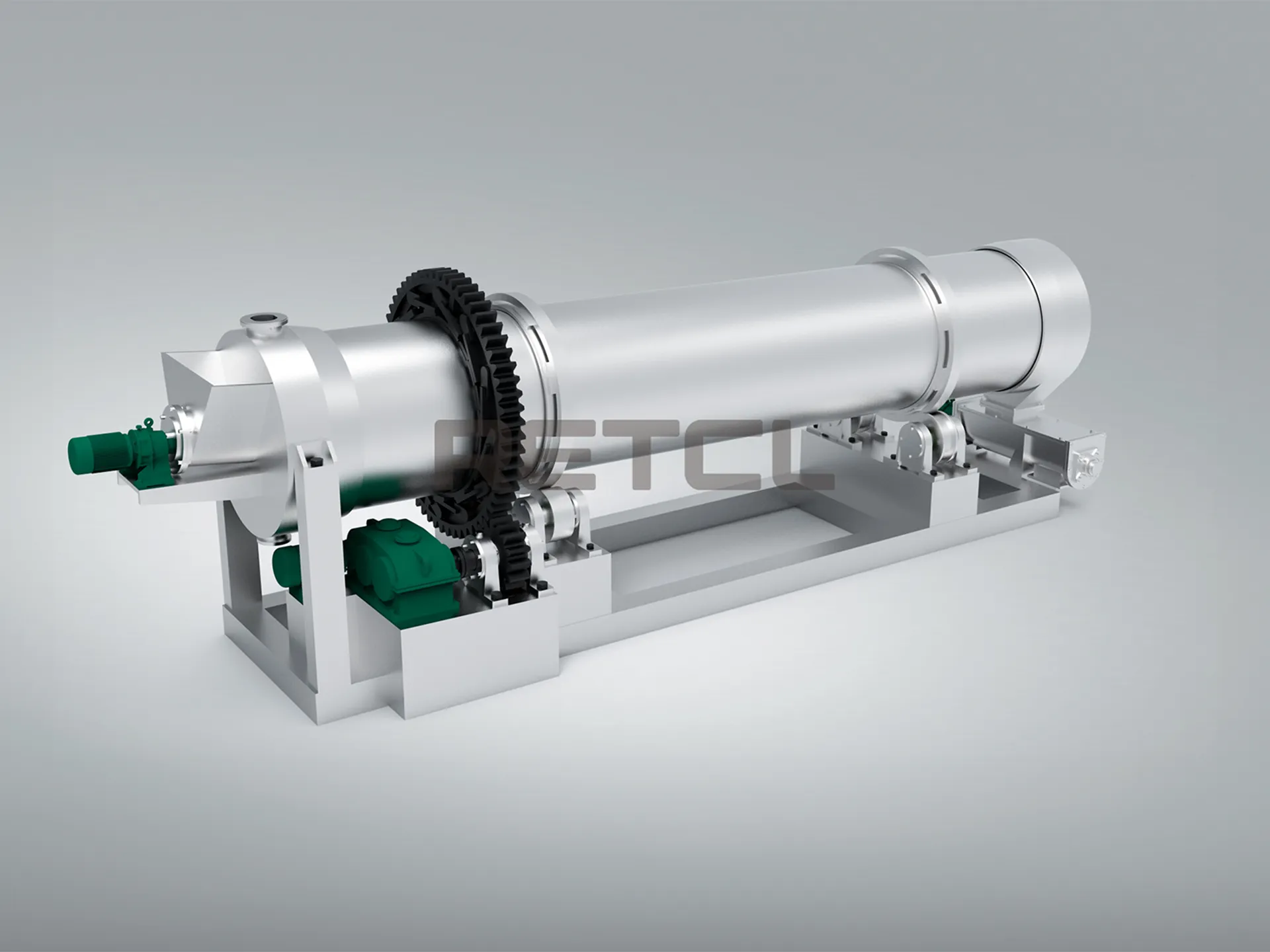

Beginning at one end of the Rotary Kiln wet materials. Are agitated by internal flights blending thoroughly with hot air. This elongated Drum dryer, spanning meters processes hundreds of tons, per hour. The Drum speeds can be adjusted from 1 to 10 RPM to suit requirements.

Input: Granular materials

Output: Granules with 3%-5% moisture content

Temperature: Inlet air temperature range of 40°C to 350°C

Additional Feature: Mixing

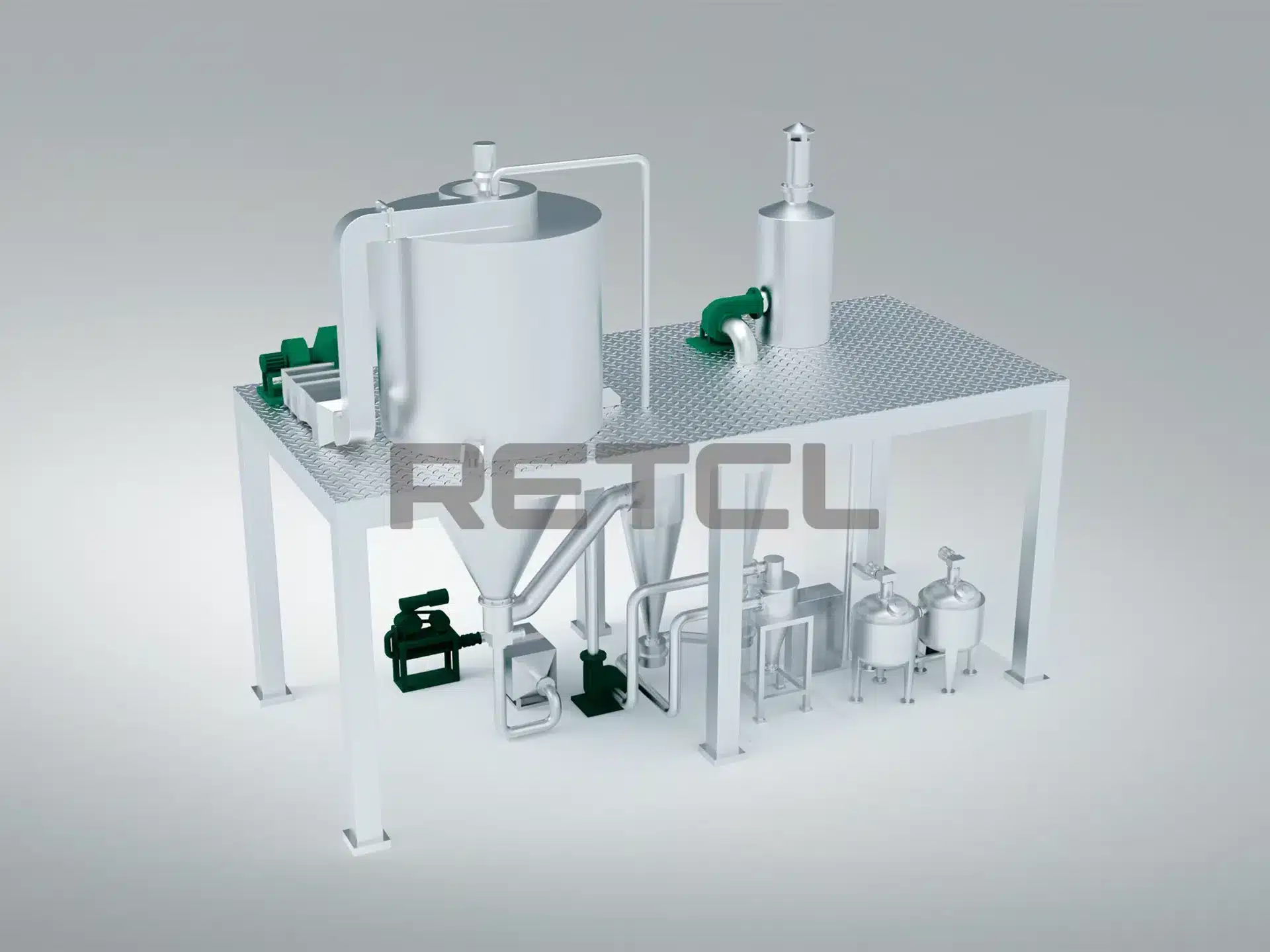

At the heart of our process, a high-speed centrifugal atomizer at the tower’s peak transforms materials into super fine liquid drops. These liquid drops dry quickly upon contact with hot air, making the centrifugal spray dryer perfect for precise particle size, moisture, density and shape standards.

Input: Solutions, Emulsions, Suspensions

Output: Powder with 3%-5% moisture content

Temperature: Inlet air temperature range of 150°C to 500°

The Spiral Vibrating Dryer effectively dries substances by using centrifugal vibration and gravity to make materials move in a bouncing manner from the top to the bottom along the spiral bed. Fresh hot air comes in from below thoroughly interacting with the material, for heat and mass transfer then leaves through the top ensuring drying.

Input: Granular,short rod and spherical solids with <20% moisture

Output: Granules,short rods and spheres with 3%-5% moisture

Temperature: Inlet air temperature <100°C

Additional Feature: Cooling

Dealing with materials that’re sensitive, to temperature and in slightly viscous form this equipment offers a wide selection of uses, for solid materials. It comes with design options allowing for the addition of drying and grinding stages to cater to various customer requirements.

Input: Non-viscous, loose solid materials

Output: Powder, granules, with moisture content of 3%-6%

Temperature: Inlet temperature <200°C

Additional Feature: Grinding

The Horizontal Fluidized Bed Dryer effectively aerates damp substances using air enabling drying or cooling. Designed for manufacturing it offers duration periods from a few seconds, to minutes guaranteeing effective processing.

Input: Powders and Granules, moisture <20%

Output: Powders and Granules, moisture 3%-5%

Temperature: Inlet air temperature <100°C

Additional Feature: Cooling

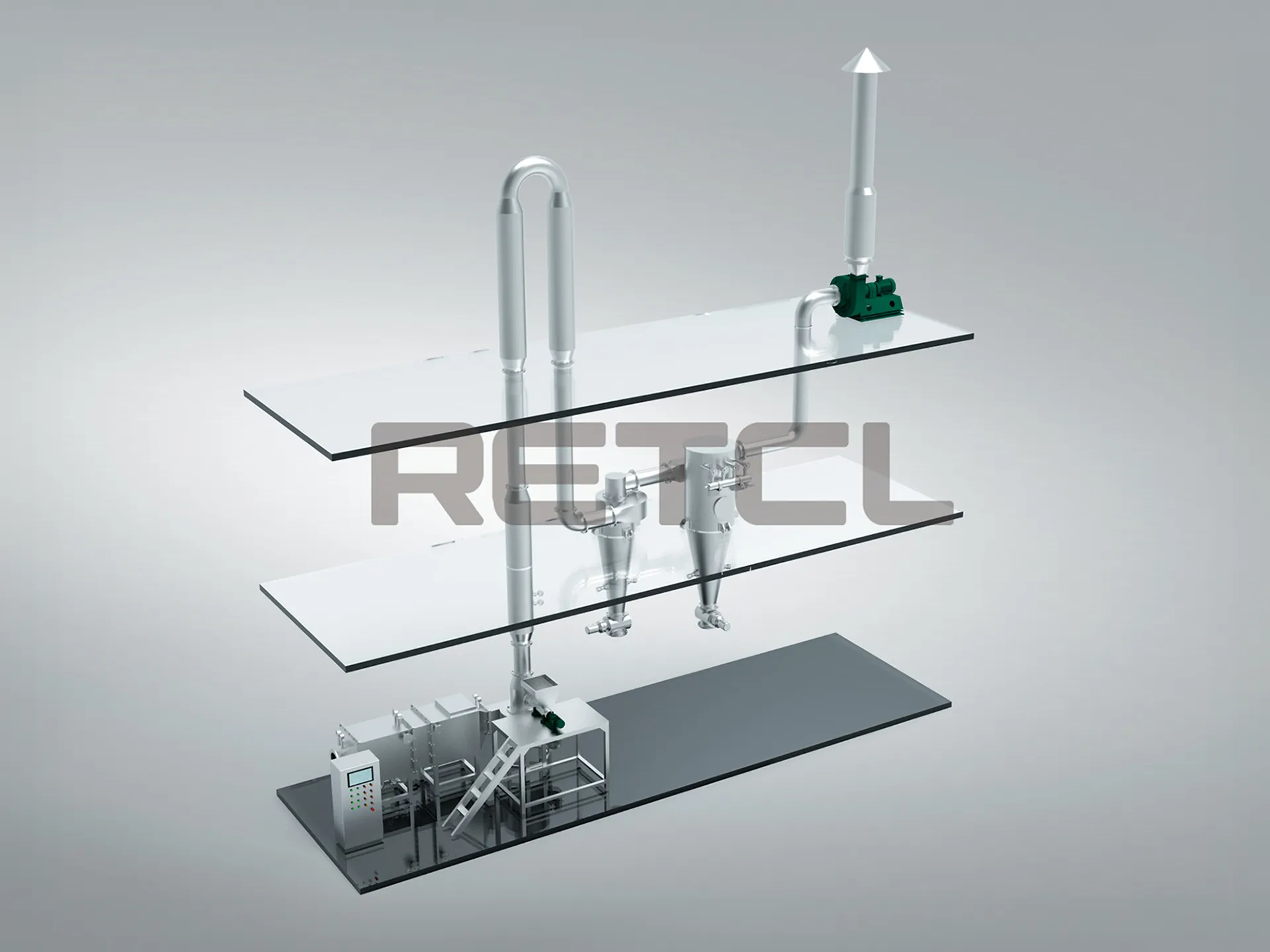

Incorporating a combination of fluidizing, pneumatic and grinding techniques this innovative unit surpasses air dryers. It is compact, efficient. Built for productivity, with seamless operation. The Spin Flash Dryer guarantees notch products by minimizing material exposure time.

Input: Loose, granular, or filter cake solids

Output: Powder

Temperature: 140°C to 220°C (standard)、below 140°C (heat-sensitive materials)

Additional Feature: Grinding

The Pressure Spray Dryer is designed to convert liquids into controlled hollow particles. This equipment utilizes high pressure pump technology along with a nozzle positioned on top for atomization. As a result it performs well in both spray drying and cooling processes. This makes it perfect, for producing spray dried granules of varying sizes to suit a range of uses.

Input: Solutions, Emulsions, Suspensions, Paste-like Liquids

Output: Small hollow particles, 3%-8% moisture content, perfect for spray dried granules

Temperature: Inlet air temperature range of 0°C to 350°C

Additional Feature: Granulation

- Commercial

- Industrial Production

- Aerospace

- Agricultures

- Animal Feed and Pet Food

- Automobile

- Biologics

- Ceramics

- Chemicals

- Cosmetics

- Dairy

- Electronics

- Environment

- Extracts

- Fats and Oils

- Foods

- Herbals

- Marine Products and Seafoods

- Metallurgy and Mining

- New Energy

- Petroleum and Petrochemicals

- Pharmaceuticals

- Plastics

- Rubbers

- Sludge

- Solid Beverage

- Spices and Flavorings

- Textiles

- Veterinary Medicine

- Woodworking and Timber

- Cooling

- Batch Drying

- Continuous Drying

- Conduction Drying

- Vacuum Drying

- High Viscosity Materials Drying

- Low Temperature Drying

- Convective Drying

- Fluid Bed Drying

- Freeze Drying

- Extraction and Concentration

- Dry Granulation

- Wet Granulation

- Fluid Bed Granualtion

- Spray Granulation

- High Shear Granulation

- Drum Coating

- Spray Coating

- Coarse Pulverizing

- Fine Pulverizing

- High Viscosity Materials Mixing

- Wet Blending

- Dry Mixing