Granulator and Extruder

Granulators and extruders play roles in industries by shaping materials into desired forms. Our selection includes Extruder Machines, Granulation Machines and more tailored to meet manufacturing requirements.

What Makes Our Granulator and Extruder Technology Stand Out?

Our cutting edge technology excels, in offering solutions known for their efficiency and precise control. Our granulators are adept at producing particles for maintaining consistent product quality. Similarly our extruders specialize in shaping materials into sizes and shapes to ensure uniformity across batches.

Benefits of Choosing Our Solutions

Selecting our machinery brings a host of advantages to your manufacturing operations. These units are crafted to optimize material processing efficiency delivering throughput, consistent product quality and minimal waste. The user friendly design of our Industrial Granulators and Extruders makes them simple to operate and maintain providing a cost solution, for your granulation and extrusion needs.

Furthermore our range of Granulators and Extruders prioritizes not efficiency but also places significant emphasis on the outputs quality and consistency. Whether handling compounds or sturdy plastic materials our technology ensures that the final product meets the highest industry standards.

Explore how our range of Granulators and Extruders can enhance your production processes. Let our dependable and efficient solutions drive your operations forward.

Explore a Range of Processing Technologies

Discover our diverse selection of processing equipment designed to optimize your production line. Explore our comprehensive solutions for your industrial needs:

- Mixer and Blender: For effective and uniform mixing.

- Pulverizer: Achieve fine particle sizes with our advanced pulverizing technology.

Materials form a fluidized bed below, where granules are created in the granulation chamber with the help of spray nozzles dispensing binders. The hopper allows for the addition of multiple raw materials, which are mixed during the fluidization process.

Input: Main ingredient as powder, adhesive in liquid form

Output: Solid medium-sized granules with 3%-5% moisture content

Type: Spray Fluidized Bed, Wet Granulation

Additional Feature: Mixing, Drying, Cooling

After the main material forms a fluidized bed at the bottom, granules are created with the aid of adhesive sprayed from the top nozzles in the granulating chamber. Subsequently, coating material is sprayed onto the granules from bottom or side nozzles within the chamber for effective coating.

Input: Main ingredient as powder (for granulation) or granules and pellets (for coating), with adhesive or coating material in liquid form

Output: Solid medium-sized granules with 3%-5% moisture content

Type: Spray Fluidized Bed, Wet Granulation

Additional Feature: Mixing, Coating, Drying, Cooling

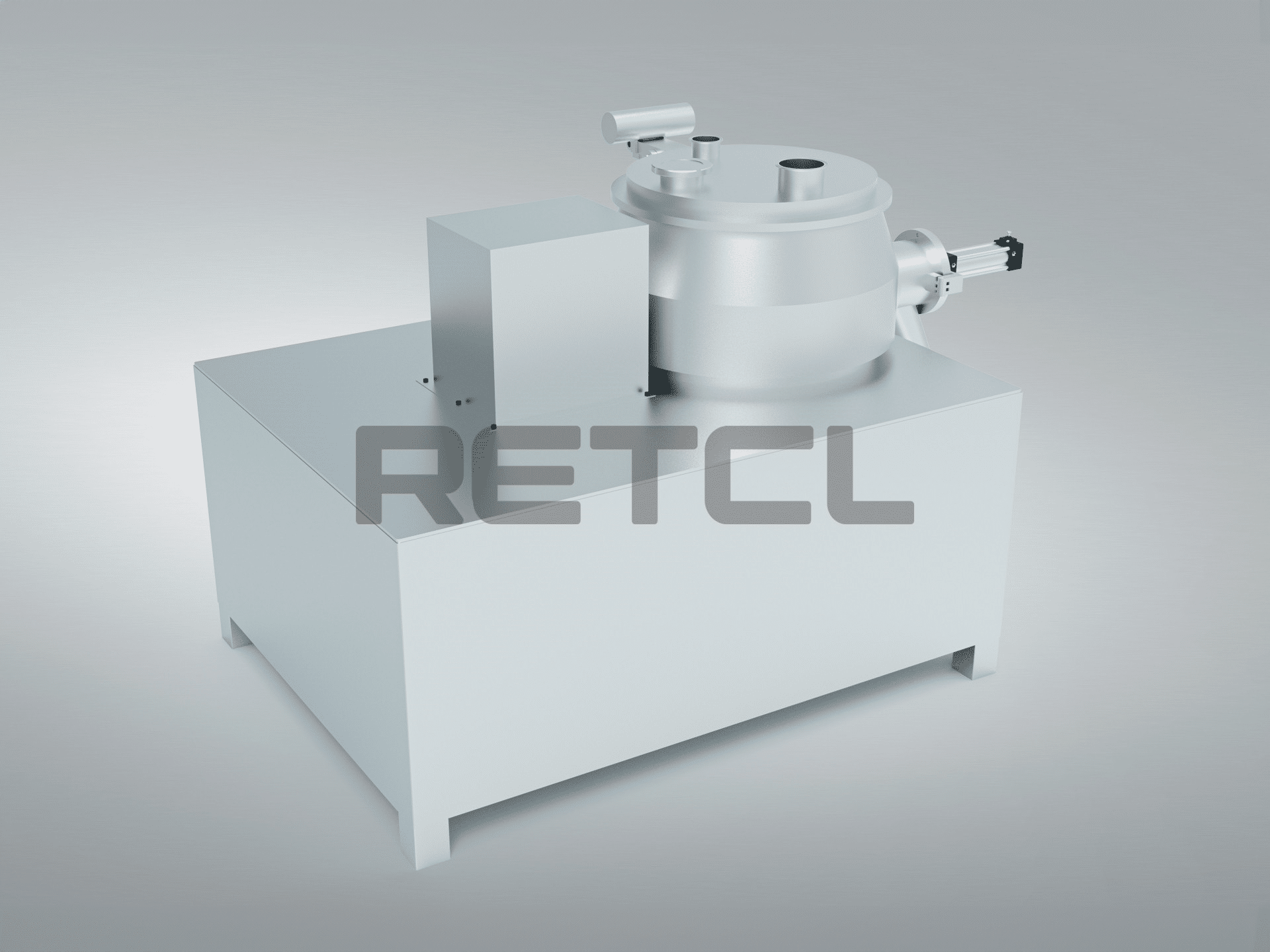

A paddle located at the base swiftly mixes powders and sticky substances within a tube shaped container. Subsequently a rapid chopper, on the side chops the mixture into wet particles to prevent clumping. This rapid process facilitates mixing and formation of particles within minutes. Moreover the Wet Rapid Mixing Granulator can provide heating or cooling as necessary.

Input: Main material in powder form, binding agent as paste

Output: Solid, loose granules with approximately 15% moisture content

Type: Mixing Granulation, Wet Granulation

Additional Feature: Mixing, Mild Crushing, Heating, Cooling

Dry raw materials are compressed under pressure to form solid flakes. These flakes are then. Processed into the desired granules.

Input: Powder

Output: Solid Granules

Type: Dry Granulation

Additional Feature: Crushing, Screening

Excipient-rich granulation processes find an ideal match in this unit. Here, excipients in the hopper form a fluidized bed, acting as seeds or carriers. The main material, typically a liquid extract constituting a smaller proportion, is sprayed from above, merging at the bed’s edge for granulation. This method is particularly suited for heat-sensitive materials.

Input: Carrier materials in powder form, main material in liquid form

Output: Solid medium-sized granules,3%-5% moisture content

Type: Spray Fluidized Bed, Wet Granulation

Additional Feature: Mixing, Drying, Cooling

By utilizing the Extrusion process wet granulation leverages the self viscosity of solid liquid dispersion to bond powder particles. This results in particles with shape and size. The Screw Extrusion mechanism generates force to create pellets without always requiring a binder, particularly suitable, for high viscosity materials. Optional water cooling is also available.

Input: Solid-liquid mixture (predominantly solid)

Output: Moist cylindrical granules

Type: Extrusion Granulation, Wet Granulation

The Oscillating Granulator uses a special moving motion to softly turn powders into even, round granules. With its variable oscillation frequency and amplitude, this granulator allows precise control of particle size and density. Compact design, simple operation and low maintenance requirements.

Input: Moist powder mixed with a binder

Output: Wet cylindrical granules

Type: Dry Granulation, Wet Granulation

Additional Feature: Mixing

Moist powder is pushed through a mesh by rotating blades during extrusion to form quality granules. The Basket Granulator offers rates of granulation visually appealing particles, automated discharge process and high output levels.

Input: Moist powder mixed with a binder

Output: Wet cylindrical granules

Type: Extrusion Granulation, Wet Granulation

Additional Feature: Mixing

- Commercial

- Industrial Production

- Aerospace

- Agricultures

- Animal Feed and Pet Food

- Automobile

- Biologics

- Ceramics

- Chemicals

- Cosmetics

- Dairy

- Electronics

- Environment

- Extracts

- Fats and Oils

- Foods

- Herbals

- Marine Products and Seafoods

- Metallurgy and Mining

- New Energy

- Petroleum and Petrochemicals

- Pharmaceuticals

- Plastics

- Rubbers

- Sludge

- Solid Beverage

- Spices and Flavorings

- Textiles

- Veterinary Medicine

- Woodworking and Timber

- Cooling

- Batch Drying

- Continuous Drying

- Conduction Drying

- Vacuum Drying

- High Viscosity Materials Drying

- Low Temperature Drying

- Convective Drying

- Fluid Bed Drying

- Freeze Drying

- Extraction and Concentration

- Dry Granulation

- Wet Granulation

- Fluid Bed Granualtion

- Spray Granulation

- High Shear Granulation

- Drum Coating

- Spray Coating

- Coarse Pulverizing

- Fine Pulverizing

- High Viscosity Materials Mixing

- Wet Blending

- Dry Mixing