Industrial Dryer and Pilot Dryer

Our wide range includes Industrial Dryers and Pilot Dryers customized to suit manufacturing needs. These drying solutions are designed to meet the demands of industries ensuring drying processes.

What Sets Apart Our Industrial Dryer Technology?

Our state of the art technology, in Industrial Drying Equipment is renowned for its efficiency and precise control throughout the drying phase. Our Dryers excel in managing volumes to ensure drying which’s essential for maintaining product quality. The Pilot Dryer, tailored for small scale experiments offers precision and efficiency on a scale for research and development projects.

Benefits of Opting for Our Drying Solutions

Choosing our Industrial Drying Machines comes with advantages. Engineered for efficiency these dryers support a high throughput process with results and minimal waste. Their user friendly design simplifies maintenance, offering a cost approach, to drying.

Furthermore our range of Industrial and Pilot Dryers not prioritizes efficiency. Also emphasizes the quality and consistency of the final product. Whether you’re drying pharmaceuticals or heavy industrial materials our equipment ensures that the end result meets industry standards.

Explore the capabilities of our Industrial Dryer and Pilot Dryer options to enhance your production line. Depend on our solutions to boost the efficiency of your drying operations.

Explore a Range of Processing Technologies

Discover our diverse selection of processing equipment designed to optimize your production line. Explore our comprehensive solutions for your industrial needs:

- Granulators and Extruders: Optimize your material processing with our advanced granulating technology.

- Mixer and Blender: Achieve uniform mixtures and consistent quality with our extensive range of mixers and blenders.

- Freeze Dryers: Perfect for preserving the integrity of heat-sensitive materials through advanced freeze drying technology.

The industrial tray dryer oven is well known for its efficiency and versatility. This drying oven improves efficiency by eliminating air while circulating air inside. It is perfect, for drying materials. Offers various tray choices such, as perforated, wire mesh and flat trays that can be tailored based on size and quantity preferences.

Input: Powders, Granules, Flakes, Strips, Blocks, Pastes, Slurries

Output: Powders, Granules, Flakes, Strips, Blocks with 3%-8% moisture content

Temperature: Inlet air temperature less than 300°C

Additional Feature: Cooling

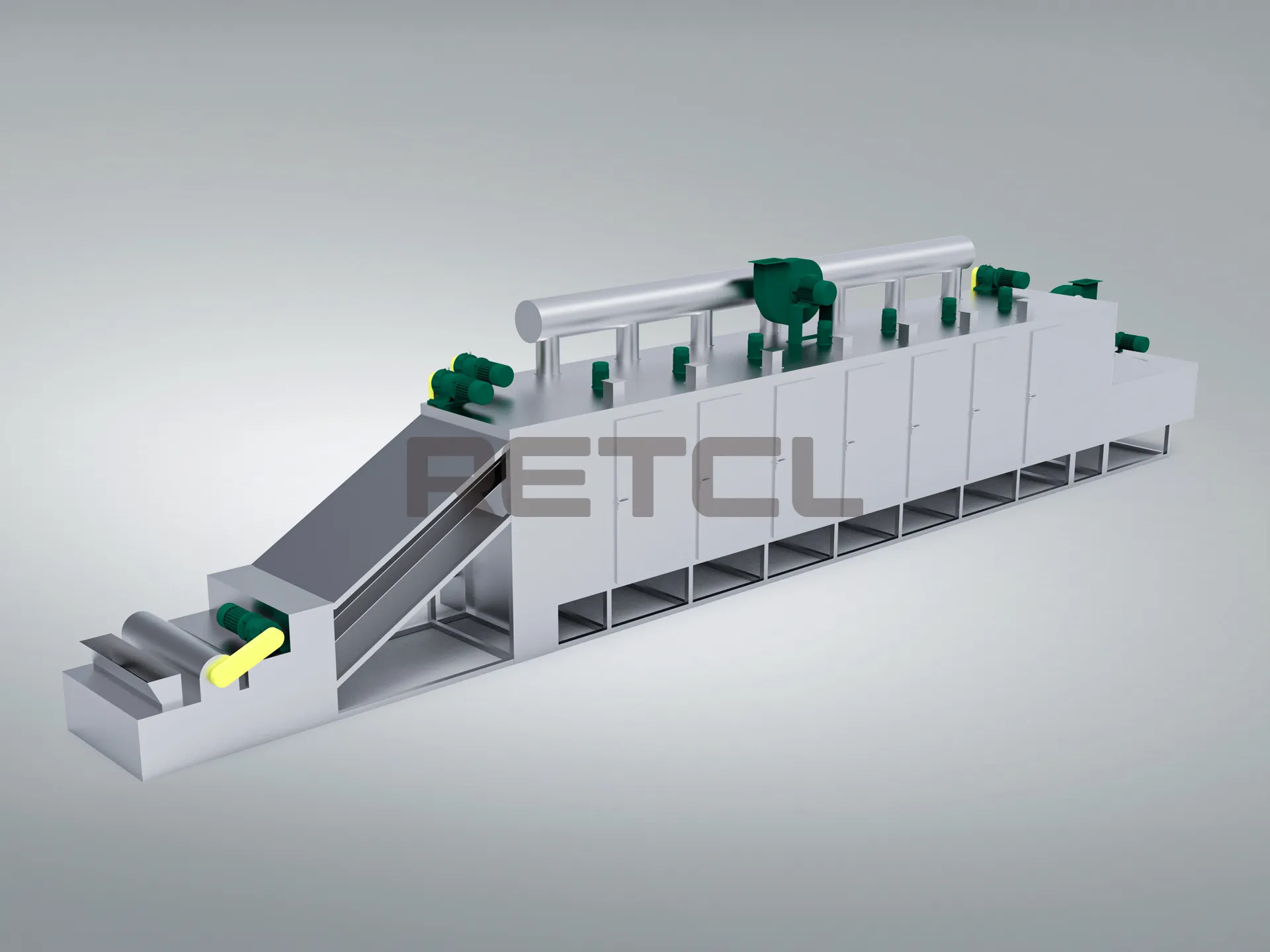

This Belt Dryer can be set up with either one or mesh layers ensuring a spread of materials, for air drying in a particular direction. Its speed can be adjusted depending on the temperature and moisture content of the materials enabling it to operate at temperatures and handle processing of sizable batches.

Input: Permeable solids in sheets, strips, granules or blocks

Output: Sheet, strip, granule or block solids with 3%-8% moisture content

Temperature: Inlet air temperature <200°C

Additional Feature: Cooling

With its jacket and ribbon design the Conical Vacuum Dryer provides a heating surface, efficient material loading and smooth discharge without any dead angles. The ribbon facilitates mixing for heating and blending processes. This dryer is perfect for operating under low temperature vacuum conditions making it suitable, for handling explosive and heat sensitive materials.

Input: Loose powdery, granular solids

Output: Powder with 3%-5% moisture content

Temperature: Heat source temperature <200°C

Additional Feature: Stirring and mixing

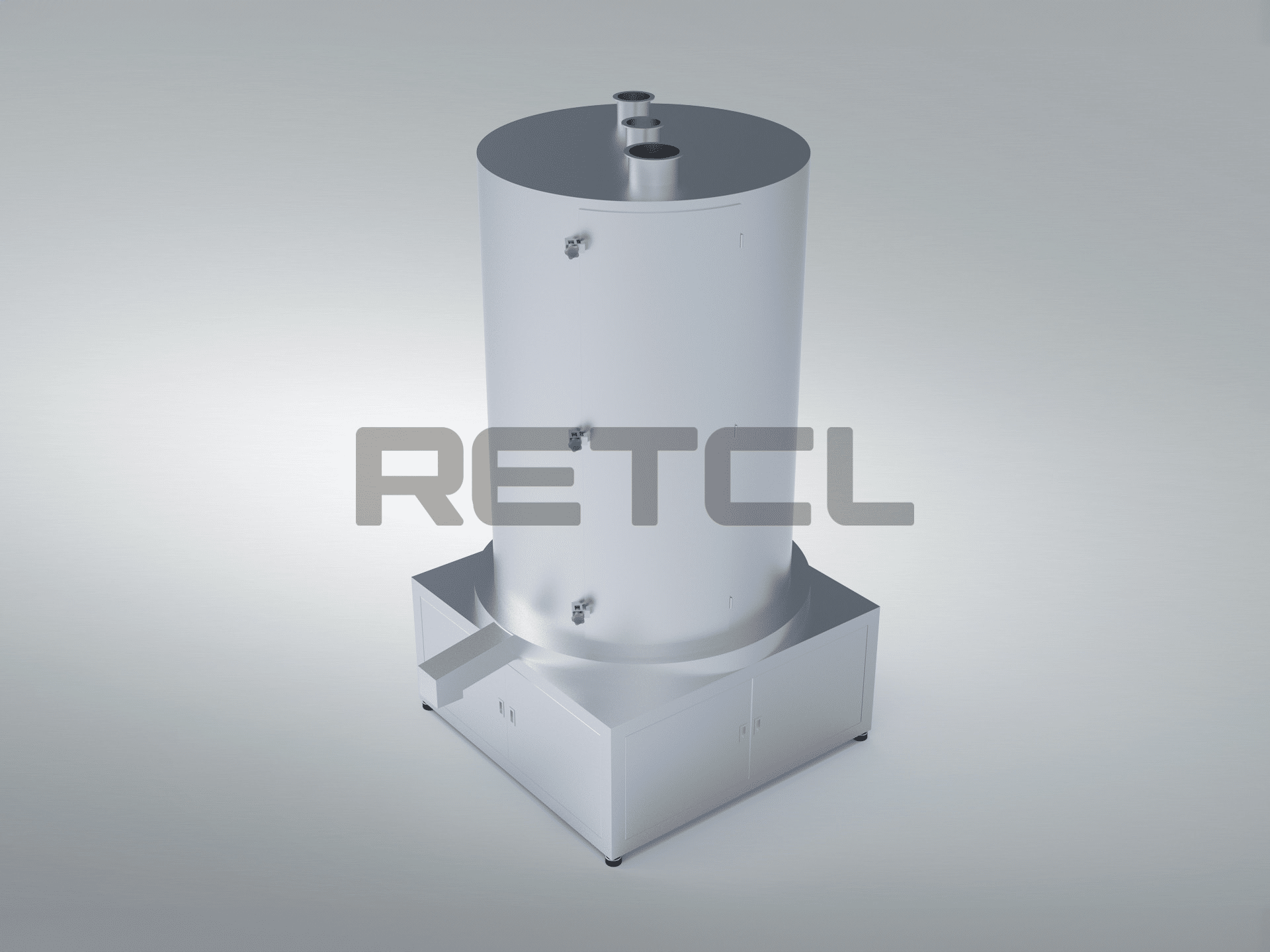

The Vertical Fluid Bed Dryer stirs materials to create a fluidized bed with air promoting contact, for quick drying or cooling. Specifically designed for batch production it allows for bed heights than horizontal fluidized bed dryers commonly paired with wet granulation machines.

Input: Powders and Granules, moisture <20%

Output: Powders and Granules, moisture 3%-5%

Temperature: Inlet air temperature <100°C

Additional Feature: Convertible to a spray fluidized bed granulator

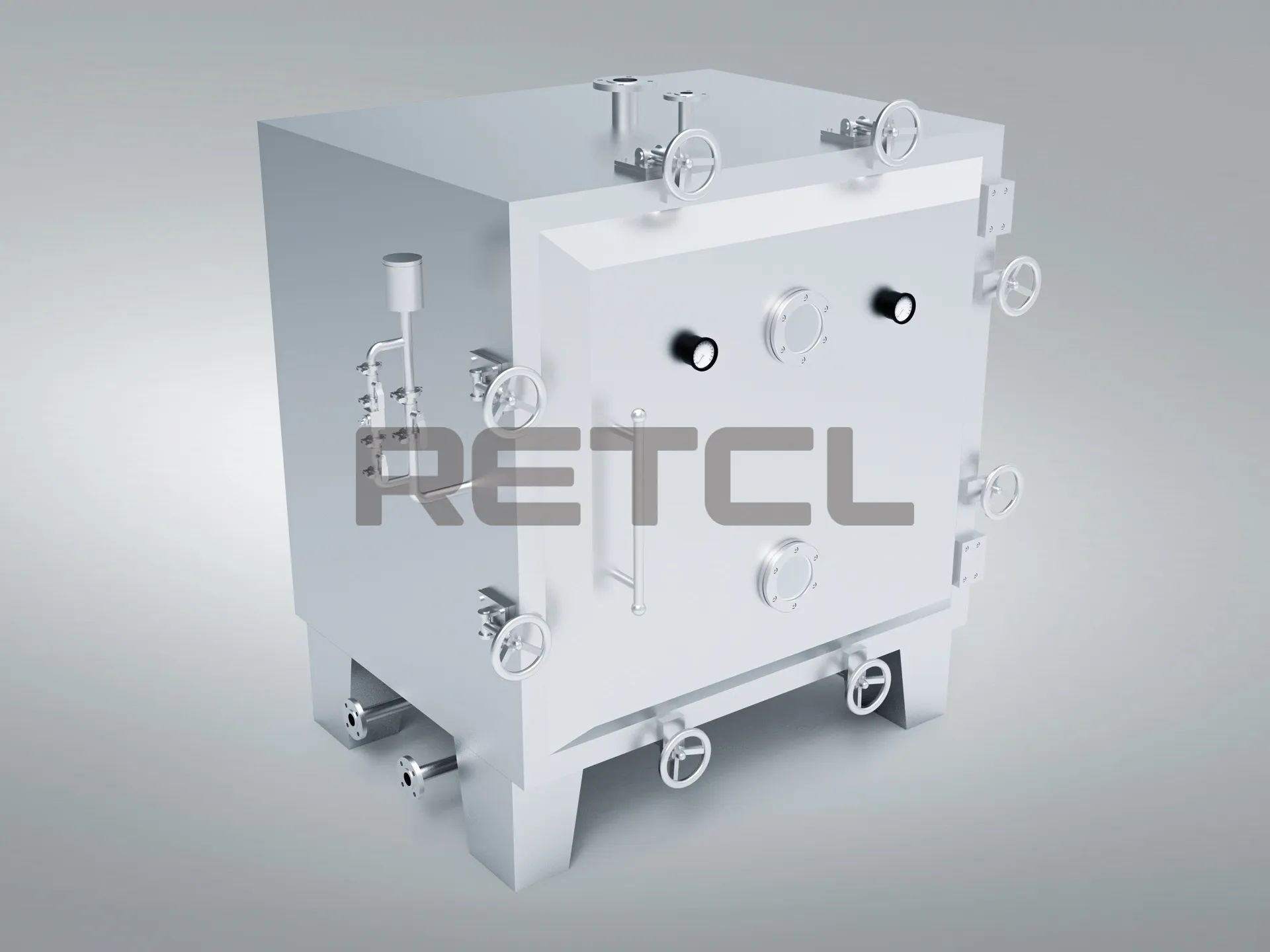

The Square Static Vacuum Dryer comes with spacious hollow heating tubes, warming materials on trays. It is perfect for operating at temperatures in a vacuum suitable, for handling explosive and heat sensitive materials while maintaining their original characteristics and properties.

Input: Liquids, Slurries, Pastes and Thick Materials

Output: Lump Solids with 3%-5% moisture content

Temperature: Heat source temperature <100°C

The Vertical Blending Fluidized Bed Dryer comes equipped with a mixing mechanism that aids in creating a fluidized bed within the container when handling heavy loads. This device is ideal for mass production. Is capable of processing thick substances typically paired with wet granulation setups.

Input: Powder and Granules,moisture <20%

Output: Powder and Granules,moisture 3%-5%

Temperature: Inlet air temperature <100°C

Additional Feature: Stirring,Cooling

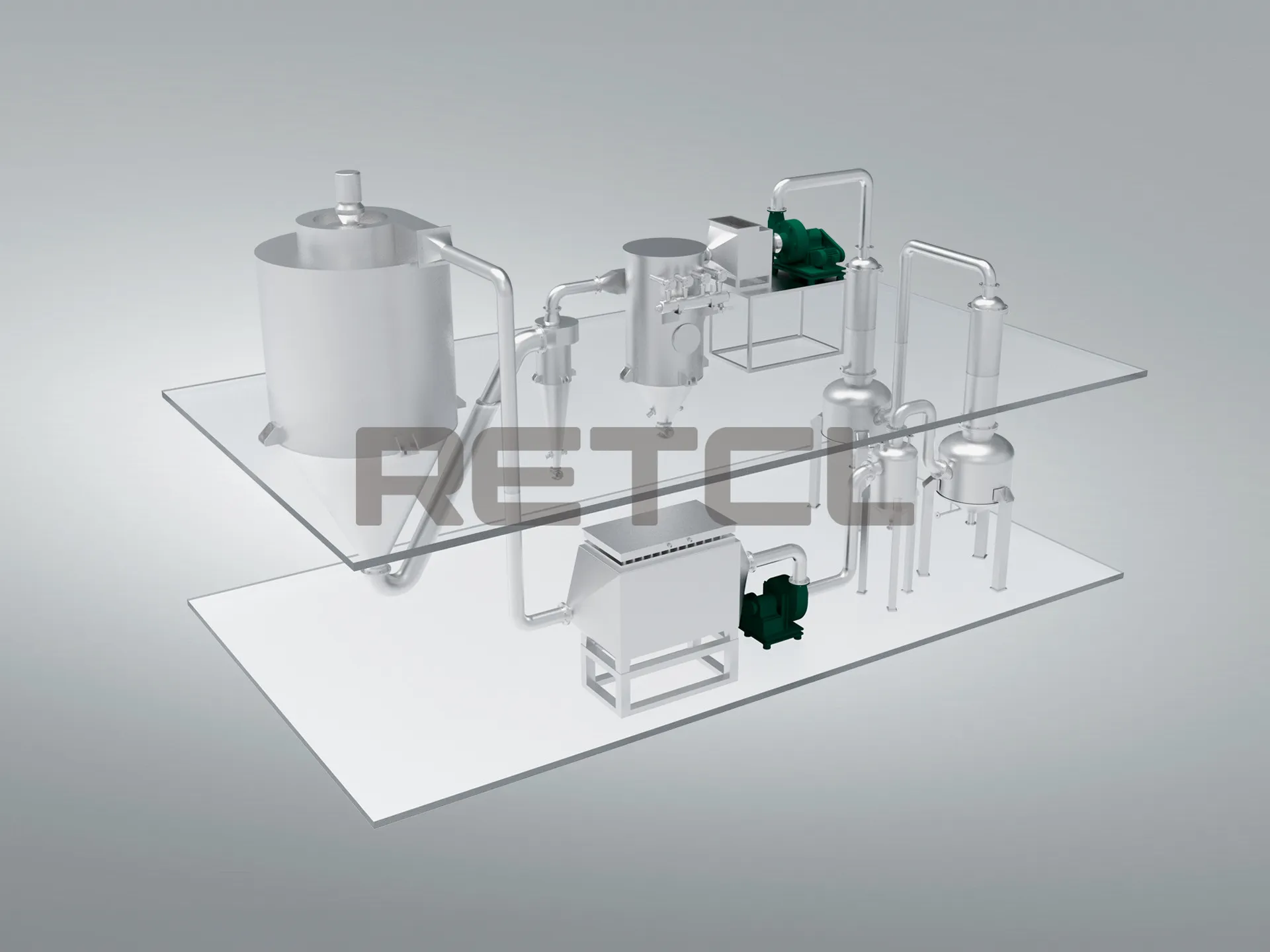

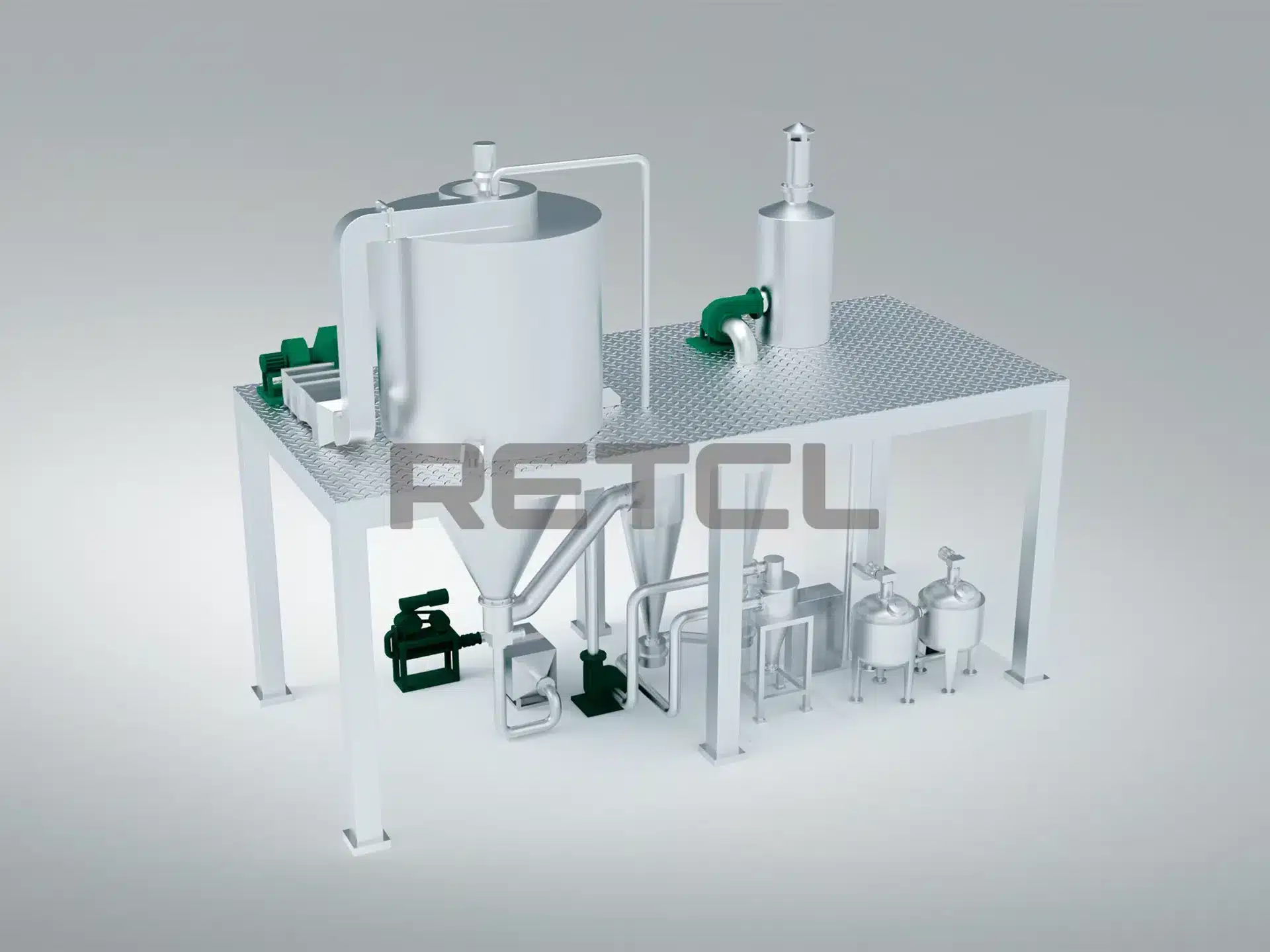

This explosion-proof spray dryer operates in a sealed environment, using inert gas as the drying medium, perfectly recovers solvents from raw materials. The recyclable drying medium ensures superior protection for sensitive materials.

Input: Solutions, Emulsions, Suspensions

Output: Powder with 3%-8% moisture content

Temperature: Inlet air temperature range of 100°C to 300°C

Suitability: Anaerobic, explosion-proof and low-temperature conditions

When using drying for paste materials the rotating drum sticks the material, onto it creating a thin layer. Heat moves from the inside, to the outside of the drum effectively removing moisture. This method guarantees drying and the inner scraper converts the material into flake shaped products quickly.

Input: Pasty,Viscous and Thick Materials

Output: Flake-like Solids with 5%-8% moisture content

Temperature: Inlet air temperature range of 120°C to 260°C

Additional Feature: Cooling

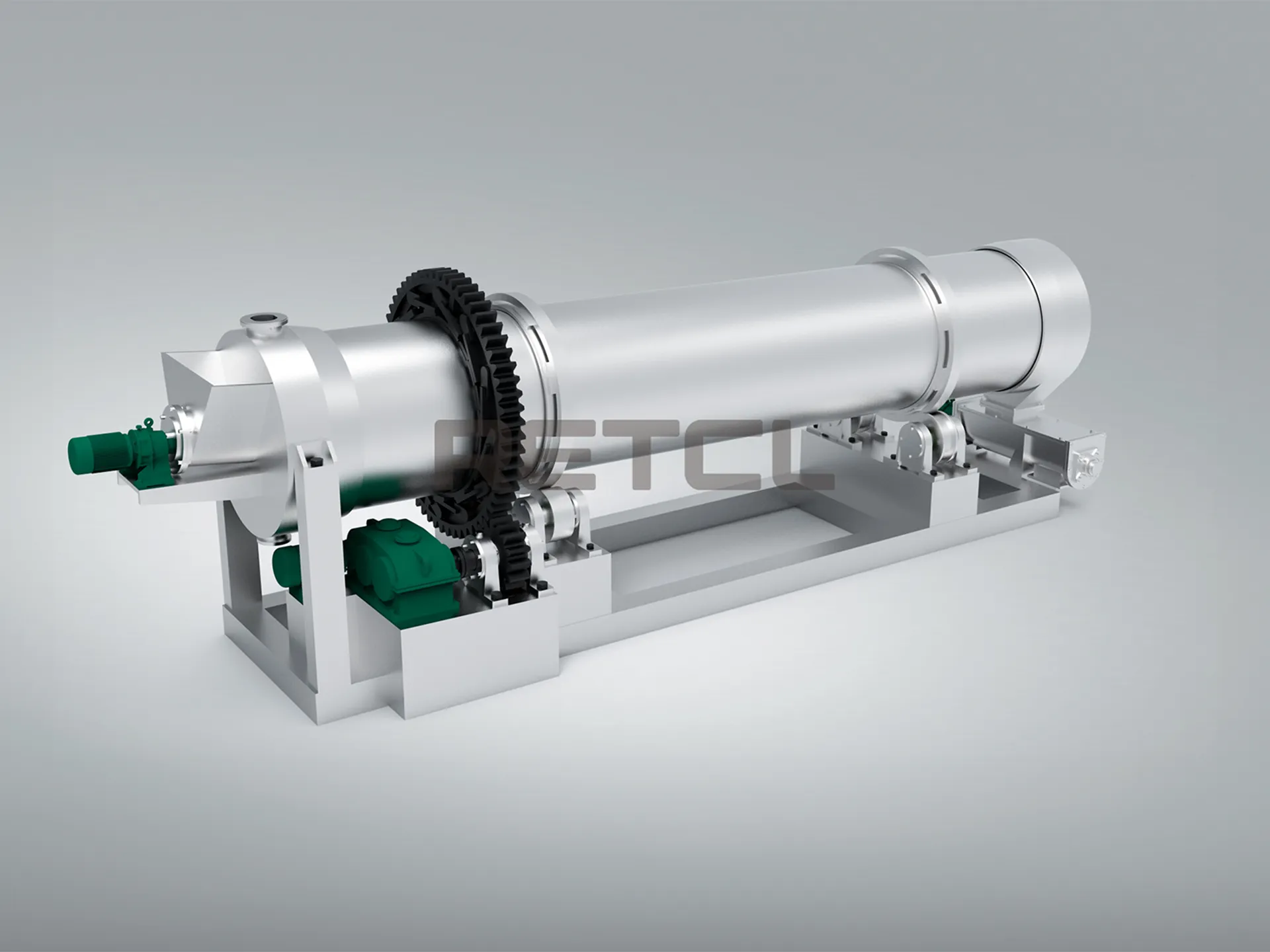

Beginning at one end of the Rotary Kiln wet materials. Are agitated by internal flights blending thoroughly with hot air. This elongated Drum dryer, spanning meters processes hundreds of tons, per hour. The Drum speeds can be adjusted from 1 to 10 RPM to suit requirements.

Input: Granular materials

Output: Granules with 3%-5% moisture content

Temperature: Inlet air temperature range of 40°C to 350°C

Additional Feature: Mixing

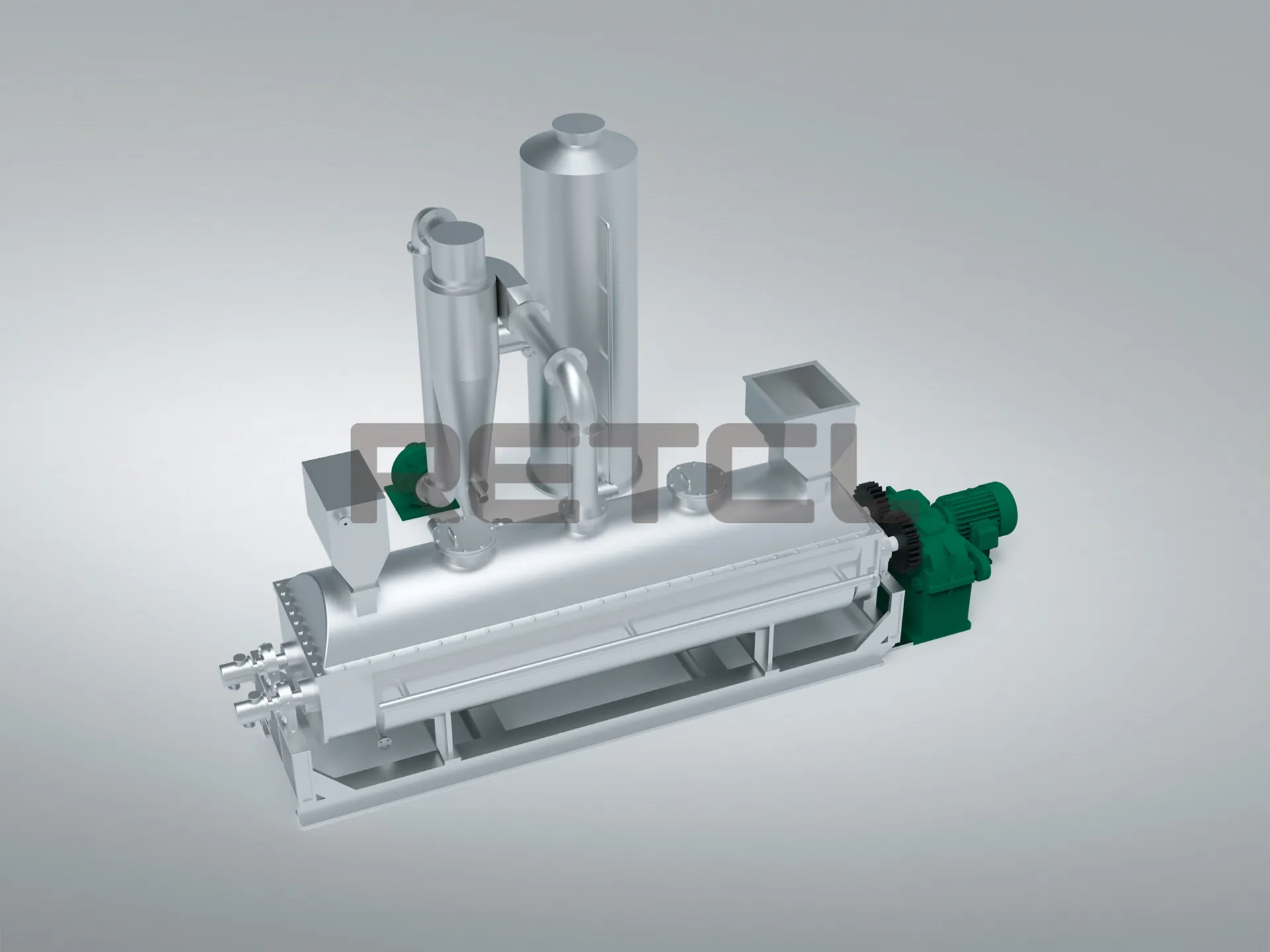

The Vacuum Conduction Dryer, with Hollow Paddle Agitator stands out with its heating surface and wedge shaped hollow paddle agitators outperforming conventional rake vacuum dryers in terms of heating effectiveness. This equipment aids in the movement and heating of materials operating under vacuum at temperatures making it suitable, for handling flammable explosive organic solvent based, as well as heat sensitive materials.

Input: Liquids, Slurries, Pastes, Mashes

Output: Powder with 3%-10% moisture content

Temperature: Heat source temperature range of 50°C to 200°C

Additional Feature: Mixing, Mild Crushing

At the heart of our process, a high-speed centrifugal atomizer at the tower’s peak transforms materials into super fine liquid drops. These liquid drops dry quickly upon contact with hot air, making the centrifugal spray dryer perfect for precise particle size, moisture, density and shape standards.

Input: Solutions, Emulsions, Suspensions

Output: Powder with 3%-5% moisture content

Temperature: Inlet air temperature range of 150°C to 500°

The Spiral Vibrating Dryer effectively dries substances by using centrifugal vibration and gravity to make materials move in a bouncing manner from the top to the bottom along the spiral bed. Fresh hot air comes in from below thoroughly interacting with the material, for heat and mass transfer then leaves through the top ensuring drying.

Input: Granular,short rod and spherical solids with <20% moisture

Output: Granules,short rods and spheres with 3%-5% moisture

Temperature: Inlet air temperature <100°C

Additional Feature: Cooling

- Commercial

- Industrial Production

- Aerospace

- Agricultures

- Animal Feed and Pet Food

- Automobile

- Biologics

- Ceramics

- Chemicals

- Cosmetics

- Dairy

- Electronics

- Environment

- Extracts

- Fats and Oils

- Foods

- Herbals

- Marine Products and Seafoods

- Metallurgy and Mining

- New Energy

- Petroleum and Petrochemicals

- Pharmaceuticals

- Plastics

- Rubbers

- Sludge

- Solid Beverage

- Spices and Flavorings

- Textiles

- Veterinary Medicine

- Woodworking and Timber

- Cooling

- Batch Drying

- Continuous Drying

- Conduction Drying

- Vacuum Drying

- High Viscosity Materials Drying

- Low Temperature Drying

- Convective Drying

- Fluid Bed Drying

- Freeze Drying

- Extraction and Concentration

- Dry Granulation

- Wet Granulation

- Fluid Bed Granualtion

- Spray Granulation

- High Shear Granulation

- Drum Coating

- Spray Coating

- Coarse Pulverizing

- Fine Pulverizing

- High Viscosity Materials Mixing

- Wet Blending

- Dry Mixing